[Contact]

Yuuki Sangyo Co., Ltd.

Takaoka Building 3rd Floor,

2-4-3 Nishi-Kanda, Chiyoda-Ku,

Tokyo 101-0065 Japan

TEL : +81-3-3263-4681

FAX : +81-3-3263-4683

Email�F yuuki@yuukisangyo.co.jp

Business hours: 9:00 to 17:30

(except weekends and holidays)

���̃}�[�N�̈Ӗ��́H |

About Permalloy

Permalloy is an alloy of iron and nickel (Fe-Ni), developed for the purpose of increasing the initial magnetic permeability.

[Origin of the name] Permeability + Alloy

Features of leading varieties

| Material variety | Magnetic material, Permalloy | agnetic material, Permalloy | |

| JIS Symbol | PC | PB | |

| Component (wt%) |

�@�@ | Ni=77�`78 Mo=5�@Cu=4 Fe=Bal |

Ni=45 Fe=Bal |

| Specific gravity | �@ | 8.62 | 8.25 |

| Breaking strength (N/m�u) |

With finish heat treatment | ��735 | 490�`635 |

| Without finish heat treatment | ��685 | 685�`885 | |

| Elongation (%) |

With finish heat treatment | O=��25 | O=��10 |

| Without finish heat treatment | H material: ��10 | ||

| Hardness (Hv) |

With finish heat treatment | 150�`190�@ | 130�`160 |

| Without finish heat treatment | ��200 | ��200 | |

| Thermal expansion coefficient �i�~10-6/���j |

�i20�`300���j | 13.6 | 7.7 |

| Thermal conductivity (cal/cm�E���Esec) |

�@ | 0.08 | 0.03 |

| Annealing temperature(��) | �@ | 1,100 | 1,100 |

| Initial relative magnetic permeability �i��i�j | �@ | 45,000 | 14,000 |

| Maximum relative magnetic permeability�i��m�j | �@ | 160,000 | 94,000 |

Major products

Material

Plate thickness 0.05 �` 1.00�o

Width 10.0 �` 250.0�o

Deep drawn precision parts

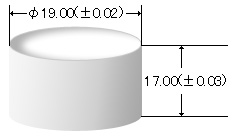

��Magnetic shield case (cap)

Dimensional tolerance (example)

Manufacturing by automated continuous press enables mass production.

Thermal treatment is done in a continuous processing line to ensure sufficient magnetic characteristics.

Precision press parts

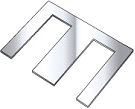

��Core (sensor) products

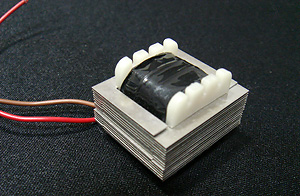

[Transformer core]

�@�@

�@�@ ![[Transformer core]](../../../img/sub/product/press/pl_t_core.jpg)

| E core | Toroidal core |

[Type EX, dimension of major cores]

![[Type EX, dimension of major cores]](../../../img/sub/product/press/permalloy_EXtype.gif)

Material: Permalloy PC (Unit: mm)

| Item No. | Thickness | A | B | C | D | E | F | G | Pieces/kg | |||||||||||||||||||

| EX-14 | 0.20 | 14.0 | 10.5 | 8.75 | 1.750 | 3.50 | 3.50 | 1.75 | 6,660 | |||||||||||||||||||

| 0.35 | 14.0 | 10.5 | 8.75 | 1.750 | 3.50 | 3.50 | 1.75 | 3,810 | ||||||||||||||||||||

| EX-16 | 0.20 | 16.0 | 14.0 | 12.00 | 2.000 | 4.00 | 4.00 | 2.00 | 4,460 | |||||||||||||||||||

| 0.35 | 16.0 | 14.0 | 12.00 | 2.000 | 4.00 | 4.00 | 2.00 | 2,250 | ||||||||||||||||||||

| EX-19 | 0.20 | 19.0 | 15.0 | 12.50 | 2.375 | 4.75 | 4.75 | 2.50 | 3,440 | |||||||||||||||||||

| 0.35 | 19.0 | 15.0 | 12.50 | 2.375 | 4.75 | 4.75 | 2.50 | 1,960 | ||||||||||||||||||||

Standard sizes are available for each type.

Please specify the dimensions for the alphabet letters on the above drawing.